Rob

The robot loads and unloads media onto the Impala 2 flatbed printer. The two of them work extra shifts together and unburden personnel from routine tasks. Automation optimizesutilization and hence returns.

Practically any sufficiently rigid material with a non-porous surface can be handled. Just a few simple steps and within ten minutes Rob is docked to the printer and ready to go. Another few mouse clicks to set up the job and then things can get started – without headaches or additional effort. Because this is where the output software takes over. It communicates both with trainable Rob and the printer.

The operator can easily switch to other tasks in the meantime, or even go home for the evening. Rob and the printer handle the extra shift all by themselves. It doesn’t get less complicated or more reliable than that. Rob is ready for action 24 hours a day, 7 days a week. He takes care of routine work uncomplainingly – with consistent precision and high efficiency. Rob even gets higher utilisation out of every swissQprint machine. Customers benefit from shorter delivery times, while providers earn higher returns.

And if there are jobs where Rob cannot help out, he is happy to be stashed away in a small corner until the next deployment. Either way, the large format printer remains accessible at all times.

Case Study

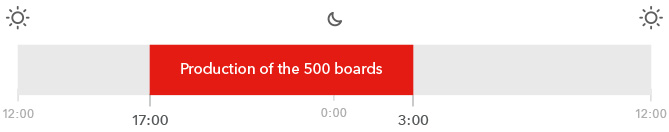

Alex operates an Impala 2. He has dealt with various jobs today: a multi-panel construction sign board, various roll jobs and a few short runs – all different dimensions. It is shortly before closing time when he receives an urgent order from a jewellery retailer. 500 promotional posters need to be printed. The perfect job for Rob.

So, before Alex leaves for the day he sets up the job:

Substrate: 1mm thick and 500×700 mm large PVC foam boards

Number of boards: 500

Printing mode: Quality mode (48 m²/h)

The stack is done in 10 hours. In other words, Rob and Impala 2 have taken over a night’s shift without supervision. Next morning, Alex delivers the posters well in time and the customer is impressed by the quality and processing time. Alex happily gets back to the print shop where a number of different jobs are awaiting him.

Substrate dimensions – maximum 700 x 1000mm

Substrate thickness – maximum 50mm

Stack height – maximum 500mm

Substrate weight – maximum 7kg per board

Robot dimensions (L x W x H) – 1464 x 1178 x 1752mm

Power connection – Powered from the printer

Power consumption – maximum 500W