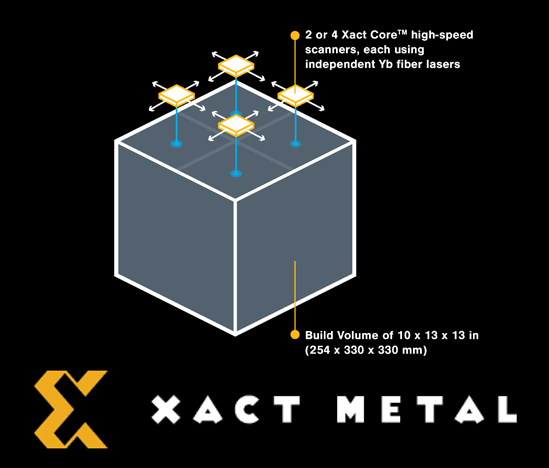

Xact Metal XM300C

The XM300C

Larger build area. Less build time.

The XM300C offers a large build volume (10 x 13 x 13 in; 254 x 330 x 330 mm) and two or four high-precision independent multi-lasers, meaning your components will be printed up to four times faster. The system uses the patent-pending Xact Core™ technology and is equipped with two feed chambers, which lowers build time and increases productivity. With advanced software capabilities, this machine is designed for industrial-grade applications.

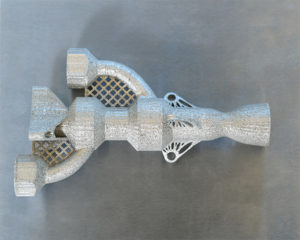

Metal powder-bed fusion provides high-quality and complex parts. It reduces total cycle time by about 50% and removes the need for wash/debinder and sintering/oven equipment used in bound metal deposition, atomic deposition additive manufacturing or other FDM-like metal 3D printers.

Shipping in 2020.

Leading Technology

Xact Core™

Making quality metal printing accessible requires innovation. Xact Metal’s printing technology is built on the patent-pending Xact Core, a high-speed gantry system platform that allows light, simple mirrors to move quickly and consistently above the powder bed on an X-Y axis.

- Avoids the use of complex rotating galvanometer mirrors and F-theta lenses

- Maintains a constant laser angle across the whole build plate

- A simplified gas flow over the powder bed due to the smaller build chamber

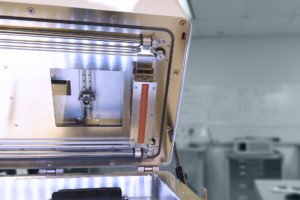

Patent-Pending Recoater

Recoater performance can directly affect the quality of your build. Our patented recoater design offers a variety of benefits.

- Unique “bulb” shape of the recoating element spreads powder like a blade, yet provides compaction similar to a rolling element

- Compliant design allows the recoater to negotiate out-of-plane growth and continue printing

- Mounting the recoater to the machine lid allows the entire recoating mechanism to be removed from the build chamber

- Easy access to the build chamber allows for simple recoater replacement and adjustments

Xact Metal offers industry-standard:

- Stainless Steel: 316L, 17-4 PH, 15-15, 400 Series

- Super Alloys: 718, 625, Cobalt Chrome F75, Hastelloy® X

- Tooling Steels: Maraging M300, H13

- Bronze