Xact Metal XM200C

XM200C Printer

Accessible Metal Powder-Bed Fusion 3D Printing

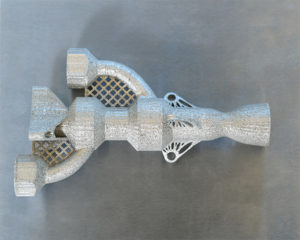

The XM200C 3D metal printer is making waves in the industry, establishing a new level of price and performance. The printer deploys fiber laser-based powder-bed fusion technology by selectively fusing thin layers of metal powder to create parts directly from a 3D-CAD model. Powered by our patented Xact Core™ high-speed gantry system, the XM200C continues to revolutionize metal 3D printing.

Leading Technology

Leading Technology

Precision Digital Scanner/Optics

- Active thermal drift compensation eliminates warm-up times and minimizes long-term drift during printing operations

- 24-bit command resolution gives industry-leading positional accuracy

Patent-Pending Recoater

- Unique “bulb” shape of the recoating element spreads powder like a blade, yet provides compaction similar to a rolling element

- Compliant design allows the recoater to negotiate out-of-plane growth and continue printing

User-Friendly Modern Design

- System is designed to allow ease of operations and minimize changeover times and has a small footprint

- Easy access to filters, particle collection and overflow container

- Quick filter changeover times using an inert swap housing

Intuitive Touchscreen

User Interface

The modern, interactive graphic user interface (GUI) for the XM200S makes loading files, setting up builds and monitoring the build process quick and easy.

- Home screen displays real-time build monitoring

- Chamber setup screen allows customer to optimize print parameters

- Build queue screen provides a description of all builds to be printed

- Monitoring screen shows behavior of important parameters such as bed temperature, chamber temperature and pressure and oxygen percentage

Xact Metal offers industry-standard:

- Stainless Steel: 316L, 17-4 PH, 15-15, 400 Series

- Super Alloys: 718, 625, Cobalt Chrome F75, Hastelloy® X

- Tooling Steels: Maraging M300, H13

- Bronze